PROLH lever hoists incorporate many of the advanced safety features that Tiger has developed including one piece construction pinion gears and our patented Quad Cam Pawl System. These units meet and exceed all the requirements within BS EN 13157: 2004+A1:2009, ANSI/ASME B30.21, AS1418.2 and SANS 1636. DNV GL Verification tested according to NORSOK R-002.

The PROLH is ideally suited for applications in the overhead transmission industry, shipyards and offshore platforms and is also suitable for underground mining use.

Our PROLH lever hoist has UK Network Rail PADS Certification - Certificate of Acceptance PA05/06651

This model also includes our unique rotational inertia driven torsion switch brake and freewheeling system. This brake system was designed by our research and design team to counter known failure modes in commonly used and copied longitudinal “push-pull” mechanisms or traditional style “Weston” type brake systems used on alternative lever hoists. This Tiger brake system is now a proven design with many thousands of hours of empirical evidence as proof of design and efficiency. This design removes the need for inefficient old style longitudinal disengagement methods of pulling the brake system apart to facilitate freewheeling. This highly efficient method of operating is not only safer but easier for the operator whilst measurably increasing the brake take up efficiency rate.

PROFESSIONAL LEVER HOIST PROLH

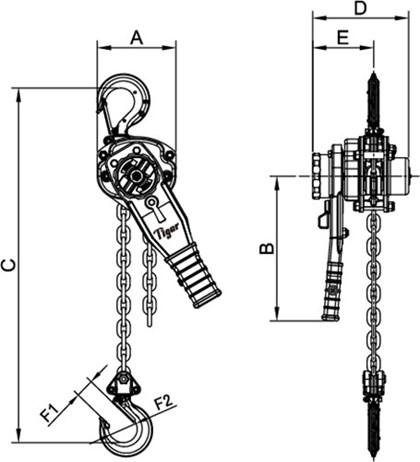

DATA TABLE

|

PRODUCT CODE |

CAPACITY (TONNE) |

EFFORT (KG) |

DIMENSIONS (MM) |

LOAD CHAIN |

STANDARD HOL (M) |

MASS KG @ STD HOL |

MASS KG FOR EXTRA METRE HOL |

||||||||

|

A |

B |

C |

D |

E |

F1 |

F2 |

DIAMETER (MM) |

NO. OF FALLS |

|||||||

|

PLH-0075 |

0.8 |

23 |

128 |

236 |

295 |

158 |

99 |

28 |

45 |

6.3 |

1 |

1.5 |

7.5 |

0.9 |

|

|

PLH-0150 |

1.5 |

26 |

154 |

360 |

320 |

172 |

104 |

34 |

51 |

7.1 |

1 |

1.5 |

10.5 |

1.1 |

|

|

PLH-0300 |

3.0 |

38 |

182 |

360 |

400 |

195 |

108 |

36 |

56 |

10.0 |

1 |

1.5 |

18.0 |

2.2 |

|

|

PLH-0600 |

6.0 |

40 |

242 |

360 |

570 |

195 |

108 |

49 |

70 |

10.0 |

2 |

1.5 |

28.5 |

4.3 |

|

|

PLH-1000 |

10.0 |

47 |

379 |

360 |

630 |

195 |

108 |

54 |

87 |

10.0 |

3 |

1.5 |

46.0 |

6.5 |

|

|

PLH-1500 |

15.0 |

44 |

566 |

360 |

840 |

195 |

108 |

59 |

81 |

10.0 |

5 |

1.5 |

112.0 |

10.9 |

|

|

PLH-2000 |

20.0 |

49 |

470 |

360 |

1050 |

250 |

160 |

81 |

110 |

10.0 |

6 |

1.5 |

156.0 |

13.1 |

|